HTML

-

TC4(Ti6Al4V)钛合金比重小、强度大,有很好的耐磨和耐蚀性,是目前最常用的钛合金,主要运用在航天航空发动机压缩机叶片、叶轮; 海洋工程的耐压壳体; 火箭导弹的外壳、船舱等等,被誉为“海洋金属”和“航天金属”[1-4]。高温氧化磨损和腐蚀磨损是TC4钛合金最主要的失效形式,所以对于它的表面性能如抗腐蚀性能、抗高温氧化性、耐磨性等要求越来越高,提升TC4合金的表面性能有很强的现实意义。常用的表面处理技术有等离子喷涂、电子束熔覆、微弧氧化、气相沉积、激光熔覆等等[5-7]。其中激光熔覆是一种将粉末通过高温激光熔化凝固在基体上的先进、高效的表面改性技术。激光熔覆的精度高、热效应低、涂层厚且可控,有优异的冶金结合性,还可以进行选择性区域熔覆用于零件增材再制造,广泛应用于TC4合金的表面改性[8-11]。TC4合金常用表面改性涂层有金属及金属合金涂层、陶瓷涂层、金属-陶瓷复合涂层几种。HUANG等人[12]在TC4钛合金上熔覆了纯铁粉,涂层上形成多种化合物,有效提高表面硬度。XU等人[13]在TC4钛合金上激光熔覆了NiCoCrAlY涂层,研究激光扫描速率对涂层质量的影响,发现涂层裂纹随扫描速率的增加而增加。KOOI等人[14]在TC4合金上激光熔覆了Ti与TiB2混合粉末,制备了Ti-TiB复合涂层,研究其组织的生长演变过程。ZHANG等人[15]通过激光熔覆的方法在TC4钛合金基体上熔覆了TiC增强钛基涂层, 有效改善了TC4合金耐磨性。

TiAl合金比普通钛合金具有更好的耐磨耐蚀性能、抗高温氧化性和抗蠕变抗疲劳性能,且其与钛合金基体界面相容性好,是钛合金表面理想的防护涂层。利用激光熔覆技术制备TiAl合金涂层成为表面改性及增材修复的前沿研究热点[16]。LIU等人[17]通过在铝合金表面熔覆无裂纹气孔的TiAl合金涂层,增强基体的抗高温氧化性。MALIUTINA等人[18]通过激光熔覆方法制备了γ-TiAl涂层,研究了涂层不同温度下的抗氧化性能。CÁRCEL等人[19]通过同步送粉熔覆的方式制备了TiAl合金涂层,研究了工艺参量与涂层性能之间影响。上述研究多采用原位合成的方法来制备TiAl合金涂层,虽然可以节约成本,但会出现中间产物或未完全反应的原材料,导致涂层性能差异大,稳定性差且难以控制[20]。

本文中直接采用商用Ti4822粉末,采用激光熔覆工艺制备出与TC4钛合金界面相容性好并满足强韧耐磨、高稳定的TiAl金属间化合物涂层,克服了常用原位合成工艺条件下反应不完全导致的涂层组织性能不均匀、稳定性差的问题;系统研究了熔覆工艺、熔覆层组织特征及物相组成及多道搭接工艺下界面及涂层内部的组织性能演变,为激光熔覆制备高强韧、耐磨损TiAl合金涂层及其工业应用提供参考。

-

基材为Ti-6Al-4V(TC4)板,熔覆粉末为Ti48Al2Cr2Nb粉末(15μm~53μm)。利用线切割得到40mm×20mm×10mm的单道熔覆基板和80mm×40mm×10mm的多道搭接基板,将熔覆面用砂轮机打磨,去掉表面的氧化层,用超声波清洗机在酒精中清洗去掉油污。

熔覆设备为YLS-6000型光纤激光器,激光光斑尺寸10mm×2mm,熔覆过程在自制氩仓中进行,氩气流量为10L/min。采用预制方式在基板上铺设1.5mm厚的合金粉末,为研究激光参量对熔覆效果的影响,控制不同的激光功率和扫描速率,得到不同功率、不同扫描速率下的熔覆涂层;多道搭接选择的搭接率为30%,40%和50%。

图 1为激光熔覆示意图和涂层截面几何量。熔覆后利用线切割得到8mm×10mm×10mm的试样,用100目~2000目的砂纸打磨截面,抛光得到涂层的金相表面,在V(H2O)∶ V(HF)∶ V(HNO3)=10∶ 1∶ 4的腐蚀液中腐蚀5s~10s,在光学显微镜下观察组织形貌;用QuantaFEG 250场发射扫描电子显微镜(scanning electron microscope,SEM)和能量色散谱(energy dispersive spectrometer,EDS)对其进行显微结构表征;采用D8-Advance, Bruker X射线衍射(X-ray diffraction,XRD)对涂层物相组成进行分析。利用Buehler维氏硬度仪测试基体和涂层的硬度,加载载荷为1kg,保压时间为10s。图中,H是熔覆高度,W是熔覆宽度。

-

表 1是6种不同工艺参量下的涂层宽度、厚度。图 2为涂层表面形貌。A2~A5涂层表面光滑没有明显裂纹和气孔等缺陷,没有出现过烧或粉末不充分熔化现象,说明功率和扫描速率在此范围较为合理,而A1和A6的功率过高和过低,导致熔池冷却凝固过慢和过快,造成堆叠现象,涂层表面粗糙。分别对比A1,A2,A3,A6,A4和A5涂层的宽度和厚度可以看出,在相同的光斑直径及熔覆速率下,功率越大涂层宽度越大、厚度越薄,这是由于功率大,熔池温度高,存在时间长,向两侧的流动越多,涂层宽度越宽厚度越薄。涂层的宽度都接近11mm,与激光直径相差不大;涂层厚度都在1.5mm~2.0mm之间,与铺粉厚度接近。这说明尽管涂层的宽度和厚度主要取决于光斑直径和铺粉厚度,但其亦受到激光功率和扫描速率的影响,对实际生产中制定合理的工艺参量具有指导意义。

No. width/mm height/mm laser power/W scanning velocity/(mm·s-1) A1 11.751 1.382 2700 2.5 A2 11.396 1.608 2500 2.5 A3 10.890 1.985 2300 2.5 A4 11.106 1.550 2300 4.0 A5 10.958 1.886 2100 4.0 A6 10.773 1.855 1800 2.5 -

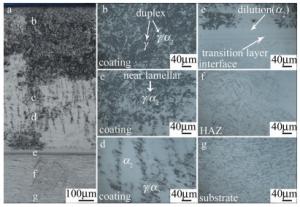

选择涂层质量较好的A4号试样进行物相及微观组织分析。图 3为涂层截面金相图。由图 3a可以看出,涂层分布均匀,没有裂纹。交界处有一条明显过渡层(见图 3e),也就是涂层稀释区,宽度不到50μm,说明稀释率低且均匀,属于冶金结合,结合性强。

钛铝可以形成Ti3Al,TiAl和TiAl3 3种金属间化合物,化学反应式为:

熔覆粉末中铝元素的摩尔分数不大于0.48,由Al-Ti二元合金相图(见图 4)[17]并结合相关文献中物相形貌分析[21-22]可知这时生成的是TiAl(γ相)和Ti3Al(α2相)。TiAl(γ相)中Al的摩尔分数比Ti3Al(α2相)高,在金相腐蚀中先析出的是TiAl(γ相)颜色较深。由图 3b~图 3d可以看出,涂层组织主要为双态组织(见图 3b,等轴γ相+片层γ/α2相),近片层组织(见图 3c,片层γ/α2相和细小的等轴γ相)和单相的α2相(见图 3d)[22]。在熔覆过程中Al元素由内向外挥发,涂层由边缘到交界,Al元素不断减少,使得TiAl(γ相)呈现不断减少的趋势;同时,图 3e为涂层和基体交界属于稀释区,Ti元素增加最多,涂层组织基本为Ti3Al(α2相)。微量元素Nb和Cr有固溶强化的作用,可有效提高TiAl合金的蠕变抗性、改善合金室温延性等合金性能[22],形成新的化合物分布在涂层中。基体热影响区(heat affected zone, HAZ)(见图 3f)属于沉积态TC4合金,微观组织主要为β相冷却时成核长大或马氏体分解形成的针状α相;基体组织(见图 3g)是在α-β相区加热保留下来的α相。

Figure 4. Al-Ti binary alloy phase diagram[17]

图 5为涂层表面的XRD谱图。其主要物相为Ti3Al,TiAl金属间化合物,微量元素化合物为Ti4Cr和Ti2AlNb,其中TiAl含量相对较少,这一方面是因粉末中Al含量较少和基体稀释造成,另一方面熔覆过程中Al元素挥发进一步使其偏离了原始粉末的成分,这与组织分布结果基本一致。图 6是图 3c的SEM形貌。图 7a和图 7b分别对应图 6中1和2处的EDS谱及其元素化学组成。由以上分析可知,图 6为近片层组织,1处为等轴γ/α2相,2处为α2相和少量细小γ相,2处Ti的相对含量(原子摩尔比)比1处高,EDS的钛铝元素组成结果与组织分布和XRD结果相符合。

-

通过间隔0.25mm直线测量从基体到涂层的硬度,得到硬度变化曲线如图 8所示。基体平均硬度为328.05HV,热影响区的平均硬度为338.93HV,涂层平均硬度为474.74HV,涂层硬度比基体高出144.67HV,是基体的1.44倍。LIU等人[23]通过激光增材制造技术,即同步送粉沉积方式制备TiAl合金涂层,涂层硬度随沉积层数增加而减小,最高可达520HV,但平均硬度不到450HV,相比之下, 激光熔覆涂层的平均硬度更高且更均匀。

-

搭接涂层是熔覆在实际生产中的关键步骤之一[24]。为了研究TiAl搭接涂层的质量,制备了TiAl的搭接式样。图 9为3种不同搭接率下的搭接样品。熔覆功率为2300W、扫描速率为4mm/s、搭接率分别为50%(见图 9a)、40%(见图 9b)、30%(见图 9c)。可以看出,搭接率为30%时,涂层厚度不均匀,熔覆凸起搭接成波浪状,导致涂层表面凹凸不平;而搭接率为40%和50%时,涂层搭接痕迹不明显,截面基本看不出单道熔覆的轨迹。搭接率为50%时, 涂层较厚,搭接铺粉厚度均为1.5mm,此时粉末的利用率最高,涂层质量也相对较好。

-

图 10为搭接率50%的涂层截面金相。图 11为图 10c的SEM图。由图 10a可知,涂层无裂纹、孔隙,涂层组织主要为全片层组织(见图 10b),双态组织(见图 10c)和近片层组织(见图 10d)。相比单道涂层,搭接涂层的单相α2相减少,这是由于多道熔覆过程中涂层受热影响作用,TiAl合金在α+γ两相区退火,γ相细化扩散到其它相区,使得γ和α2相转变为γ/α2相[25],生成片层组织,导致涂层交界处(见图 10e)的稀释区不明显,TiAl和Ti3Al的分布更均匀;而搭接涂层的热影响区(见图 10f)和基体组织(见图 10g)与单道熔覆组织相同。对比图 11和图 6,两处均为近片层组织,但明显单道涂层的γ相较为粗大,搭接涂层片层状组织分布更加均匀,这是γ和α2相转变为γ/α2相的结果[26]。

-

图 12为搭接涂层截面宏观形貌示意图(见图 12a)及其硬度分布曲线(见图 12b、图 12c)。以间隔为0.25mm的距离测试搭接试样的硬度,涂层平均硬度为484HV。图 12b为涂层截面从一条脊线到下一条脊线的横向硬度曲线,可以看出,在接近脊线位置涂层硬度较高,平均硬度可达到494HV,而两道脊线中间位置的平均硬度只有472HV,与单道涂层硬度相差不大。原因可能是两次熔覆接痕位置(如图 12中B点处)的粉末很少甚至没有,搭接熔覆只是对接痕位置做了一次激光熔凝从而提高了涂层硬度,而其它位置的硬度与单道涂层的硬度相同。图 12c为脊线下方AB和两脊线中部CD从基体到涂层的竖向硬度曲线,可以看出,CD处的涂层硬度与单道涂层的相差不大,涂层的平均硬度为470HV,AB处的涂层平均硬度为492HV,两处结果与涂层横向硬度分布结果一致。搭接涂层的热影响区平均硬度为339.87HV,与单道熔覆热影响区相比几乎无变化。但搭接涂层AB和CD处的基体平均硬度分别为382.64HV和375.98HV,与单道熔覆基体相比提升了超过50HV,提升原因是多次熔覆高温,使得基体在氩气环境下进行了一次短暂热处理。

2.1. 单道熔覆TiAl涂层的组织性能

2.1.1. 工艺参量对涂层质量的影响

2.1.2. 物相及微观组织分析

2.1.3. 硬度分析

2.2. 多道搭接涂层的组织性能

2.2.1. 多道搭接涂层的宏观形貌

2.2.2. 多道搭接涂层的显微组织

2.2.3. 多道搭接涂层的硬度分布

-

(1) 在激光功率为2.1kW~2.5kW、扫描速率为2.5mm/s~4mm/s之间都可获得较好的熔覆表面质量,搭接率为50%时,可获得最佳的搭接表面质量,涂层内没有裂纹和孔隙,且涂层与基体有结合过渡带,属于结合性强的冶金结合,证明了Ti4822粉末与TC4有很好的冶金性能。

(2) 单道涂层的微观组织主要为双态组织、近片层组织和单相α2相,搭接涂层的微观组织主要为全片层组织、近片层组织和双态组织;搭接涂层组织比单道涂层组织分布均匀,片层组织分布更广,这增加了组织的抗蠕变性。单道涂层平均硬度可达到470HV以上,是基体的1.44倍。多道搭接涂层硬度呈交替分布,高硬度区在脊线附近可达到490HV以上,低硬度区在两脊线之间平均为470HV左右。

(3) 无论是从表面质量、涂层组织或是涂层硬度,搭接涂层的质量都比单道熔覆的有所提升。证明了采用激光熔覆制备TiAl金属间化合物涂层,可以保证大范围熔覆时的涂层质量,是一种实际可行的基体表面改性方法。

Map

Map

DownLoad:

DownLoad: