HTML

-

铝合金耐腐蚀、重量轻; 双相钢成本低、强度高, 二者均被广泛应用在航空航天、船舶制造等领域[1-3]。随着制造行业的发展,单一结构的构件无法满足使用要求,异种材料的应用逐渐普遍,钢/铝两种工业中常用材料,异种焊接无可避免。但两种材料的物理性能和化学成分差异较大,在焊接过程中两种材料之间的低混相性导致焊缝的冶金相容性较差容易产生热裂纹、气孔、未熔合和等缺陷[4-6]。

激光摆动焊接具有热输入量高、使加工材料残余应力小等优点,在异种材料焊接的领域具备广阔的应用前景[7-8]。目前已有学者使用激光摆动焊接金属材料。WEN等人[9]使用激光摆动焊接6A01-T5铝合金,通过观察接头气孔的分布和微观组织,对比不同焊接方法对接头的影响,研究结果表明,激光摆动焊接得到的接头显微硬度和拉伸力得到显著提升。LI等人[10]通过使用5种激光摆动方式叠焊不同厚底的301不锈钢板,对焊缝成形和气孔率的影响规律进行分析,得到结论:相较于常规焊接激光摆动焊接得到的接头表面成形好、气孔较少、剪切强度较高。LI等人[11]使用两种摆动模式和一种直线模式焊接钢/铝接头,通过宏观形貌、接头元素分布、剪切强度的对比,发现使用激光摆动模式焊接的钢/铝接头具备更好的性能。CHEN等人[12]将线性焊接与摆动焊接的Q235钢接头进行对比分析,通过金相组织、抗拉强度、显微硬度的对比得出结论:摆动焊接对焊接接头有有利的影响。DIMATTEO等人[13]使用激光摆动焊接铜铝薄板,研究不同焊接方式、激光功率、焊接速率、光束摆幅对焊缝宽度、熔宽、熔深的影响,结果表明,铝上铜下的焊接方式具备更好的焊接质量,摆动幅度对焊缝长宽比的影响较大。

目前,针对不同摆动频率、不同摆动图案对焊接结果影响的研究较多,对激光功率的变化影响焊接结果的研究较少,因此,具备一定的研究价值。本文中对5083铝合金和DP780双相钢进行激光摆动焊接,研究不同的激光功率对焊缝成形、金相组织以及力学性能的影响,拟为激光摆动焊接在工业上的应用提供参考。

-

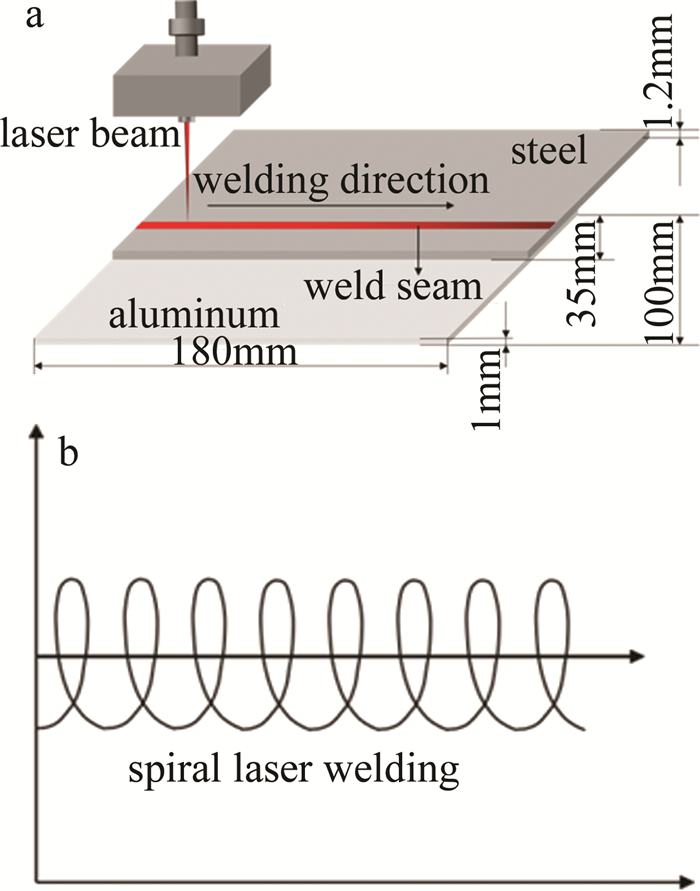

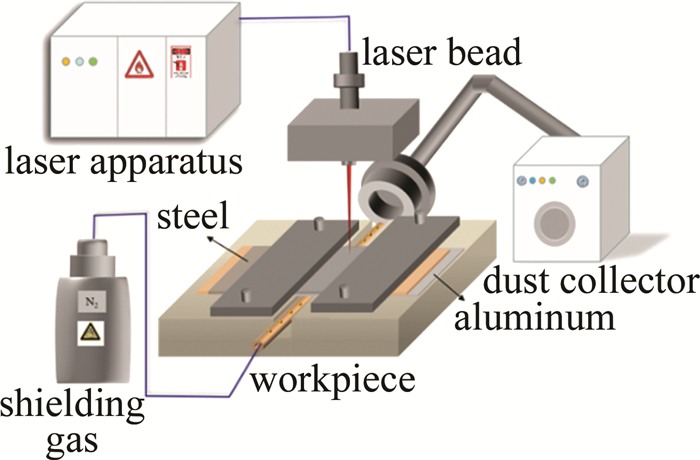

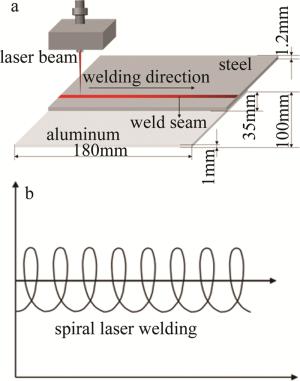

实验中使用1.3mm厚DP780双相钢和1mm厚的5083铝合金板材的尺寸均为180mm×100mm,主要化学成分如表 1所示。搭建图 1所示的焊接系统。采用Trumpf 10002碟片激光器,激光束通过光纤进行柔性传输,传输光纤最小直径为200μm。采用最大功率10kW的连续激光器,输出波长1030nm,额定功率下的功率输出稳定性为±1%。

material Mn Si Ti Mg C P S Zn Cr Al Fe DP780 0.0195 0.00235 — — 0.0016 0.00022 0.00007 — — 0.00132 balance 5083 0.005 0.001 0.0003 0.047 — — — 0.0003 0.001 balance 0.003 Table 1. Main chemical composition of substrate material (mass fraction)

-

实验中采用钢上铝下的搭接方法,示意图如图 2所示。搭接距离为35mm,用氮气保护,氮气的流速是15L/min。

影响焊接结果的主要因素有:激光功率、焊接速率和离焦量,其中激光功率对焊缝的影响最为显著。因此本文中主要研究激光功率对焊缝宏观形貌、微观组织、显微硬度和焊缝拉伸性能的影响。根据以往的焊接经验,激光功率在1400W~1600W之间焊缝成型效果较好[14],为获得良好的焊接效果焊接功率的窗口范围,设计如表 2所示的实验参数。

serial No. laser power/W wobble breadth/mm wobble cycle/mm wobble frequency/Hz welding speed/ (mm·s-1) 1# 1300 1 0.786 28 22 2# 1400 1 0.786 28 22 3# 1500 1 0.786 28 22 4# 1600 1 0.786 28 22 5# 1700 1 0.786 28 22 Table 2. Welding parameters

使用钢刷打磨钢铝材料,使用工业乙醇进行清洗,除去表面多余油脂和杂质。沿着焊缝垂直方向切割拉伸和金相试样。切割后的金相试样使用800#、1500#、2000#的砂纸依次打磨表面,然后使用金相磨抛机(UniMP-202)对试样进行机械抛光以得到光泽镜面。使用V(HF): V(HNO3): V(H2O)=1:2:7的溶液对试样表面进行腐蚀,使用平面测量显微镜(VH1202)和数字化金相显微镜(Ario Image.M2m)对焊缝形貌和微观组织进行分析。使用显微维氏硬度计(Buehler VH1202)测量焊缝的显微硬度,测量标准选用ASTM E384,测量时加载力为500g,保压时间为10s。拉伸试验使用电子万能拉伸试验机(上海捷沪CMT4202),拉伸试样规格为20mm×130mm,实验时,分别在两侧的母材处加入1.2mm和1mm厚度的垫板,保证拉伸力与接头界面平行。

1.1. 实验设备

1.2. 实验方法

-

激光功率过大或过小,都会使钢/铝两种材料焊接失效。当采用较小的激光功率时,激光辐照在钢板表面,产生的能量较低,无法完全熔化钢铝两种材料,产生熔池。当采用较大的激光功率时,激光辐照在材料表面,虽然可以完全熔化两种材料产生熔池,冷却速率低,但是熔池存在时间较长,熔池内的金属蒸发量增多,容易产生裂纹、板材焊穿的情况,致使连接失效[15]。使用spiral模式摆动焊接钢/铝薄板的有效功率区间在1400W~1600W,图 3为不同激光功率下焊缝的宏观形貌。通过观察可以看出,使用1400W功率焊接的焊缝成形效果最好,焊缝整体呈银白色,表面纹路清晰,飞溅较少;使用1500W的功率时,焊缝飞溅增多,焊缝有少量氧化物,这是由于熔池内的由于合金元素的烧伤所导致[16];当激光功率为1600W时,焊缝整体下榻、氧化严重、飞溅增多、接头下榻,成型效果差。

-

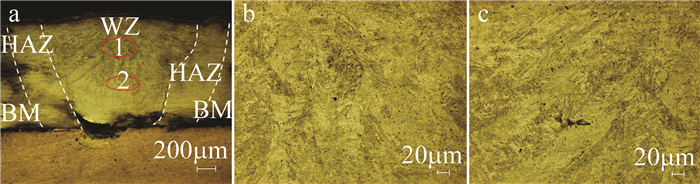

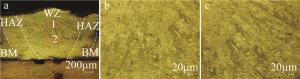

焊接接头主要由热影响区(heat affected zone,HAZ)、熔合线(fusing line,FL)、焊缝(weld zone,WZ)三部分组成,因为激光摆动焊接对接头热影响区部分无明显影响,因此通过金相显微镜观察不同功率焊接接头上下两部分的金相组织,并对其进行分析。当激光功率为1400W时,如图 4所示。图中, BM(base metal)是激光融化母材。接头上下两端的金相组织均为马氏体,与上侧、下侧的马氏体尺寸相比相对较小,这是因为上侧吸收的激光热源较多,有足够的能量支撑晶粒成长。

当激光功率为1500W时,如图 5所示。焊缝顶端和底端为马氏体,相比于2#焊接接头,马氏体的尺寸略大,在焊缝底端有少量带状分布的铁素体。在马氏体上颗粒状的黑点为碳化物。

当激光功率为1600W时,如图 6所示。焊缝内产生大量铁素体,在焊缝的顶端有少量的片状珠光体,在铁素体和马氏体交接的地方产生少量的马氏体。随着接头熔深的增加,铁素体的含量逐渐增多。接头上下两侧为铁素体,中间为少量片状珠光体和马氏体,4#接头整体由铁素体组成。

激光熔化钢铝两种材料,即可产生钢铝熔池。过大的激光功率在产生熔池后依然有多余的能量满足晶粒的生长,导致接头内晶粒粗化。过大的晶粒会使组织之间与组织内部的结合力小,成为焊接的薄弱点[17]。过小的激光功率熔化金属形成熔池后,剩余能量较低,此时晶粒成长受限制,晶粒细小。随着激光功率的增加,熔池存在时间变长,接头内的马氏体逐渐过渡为铁素体。马氏体具备优良的性能,主要表现为焊接接头的显微硬度与最大拉伸力的提升,因此2#和3#焊接接头的力学性能相对优良。

-

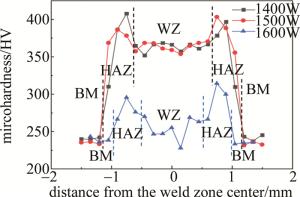

图 7中为不同焊接模式下钢侧接头的显微硬度。根据图片观察可以看出,使用激光焊接钢侧接头,可显著提升接头的显微硬度。3种焊接接头热影响区的显微硬度均高于焊缝中心。其中使用1400W和1500W的功率焊接的接头显微硬度更高。DP780双相钢母材的显微硬度约为240HV,2#接头和3#焊接接头的显微硬度最大值分别为407HV和403HV。相比与母材2#和3#接头的显微硬度提高1.69倍和1.67倍。激光功率和熔池的冷却速率呈正比增加,熔池存在时间长,会过渡蒸发熔池内的金属,使接头产生下榻、裂纹、气孔等缺陷,对力学性能产生影响[18-19]。较大的功率也会导致焊缝内的晶粒尺寸过度生长,因此在低功率下的马氏体转变为铁素体,马氏体力学性能相对优良,主要表现为焊接接头的显微硬度与最大拉伸力的提升。

图 8展示不同激光功率下,焊接接头的宏观拉伸形貌和剪切强度。在3组接头中,最大剪切强度为113N/mm,最小剪切力为92N/mm。3组焊接接头拉伸的失效形式均为钢/铝结合界面失效。失效的主要原因是在接头结合处存在大量的脆性钢铝金属间化合物(intermetallic compound, IMC),在拉伸力的载荷下,IMC中的裂纹逐渐生长,引起接头结合失效,最终导致结合面在铝侧基体脱离[20]。

当使用1400W的激光功率焊接时,激光仅能熔化钢、铝基体材料形成熔池,导致钢、铝两种材料结合较少,两种材料并未完成较深的熔覆;当使用1500W的功率焊接时,下方铝板熔化面积增大。两种材料融合量增大,但熔化的钢铝两种材料有限,IMC层的生长受到限制,因此接头冶金结合强度得到提高;当使用1600W的功率时,钢铝两种材料大量融合,接头产生较厚的IMC层,在IMC层中容易存在微裂纹,导致接头冶金结合强度较低。

2.1. 宏观形貌

2.2. 金相组织

2.3. 力学性能

-

使用1300W~1700W的功率,在spiral模式下激光摆动焊接钢、铝异种材料。对比了不同功率对钢/铝异种焊接接头宏观形貌、金相组织和力学性能的影响。

(1) 使用spiral模式摆动焊接钢/铝异种材料激光功率的有效区间在1400W~1600W之间,功率过小或过大,都将导致连接失效。过小的功率无法实现板材的有效连接,过大的功率会使焊接接头出现咬边的下榻的缺陷。

(2) 激光功率的变化,意味着接头内金相组织的种类和晶粒的大小发生变化。随着功率的增加,接头内铁素体的含量增多,马氏体的含量降低。金相组织的变化意味着力学性能的改变,其主要体现在显微硬度和剪切强度上。

(3) 激光摆动焊接可以有效提高焊接接头的力学性能,焊接后3种接头钢侧的显微硬度均高于母材。2#接头的显微硬度最高为407HV,约为母材的1.69倍。3种焊接接头中,3#接头的剪切强度最大,达到113N/mm。

Map

Map

DownLoad:

DownLoad: