HTML

-

TC4(Ti-6Al-4V)合金具有较好的硬度和耐磨、耐腐蚀等优良性能,在航空航天航海等环境较为复杂的环境下应用较为广泛,尤其在高端装备制造零部件的生产加工方面,是不可或缺的制造材料[1]。由于在特殊恶劣的环境状态下使用,TC4钛合金零部件表面存在较为严重的腐蚀和磨损现象,导致钛合金部件在使用过程中存在不同程度的损坏和老化失效,如未对其及时修复和保养,会严重影响相应设备的使用寿命和使用安全。因此,为了提高TC4钛合金表面的耐磨耐蚀耐氧化性能,采用先进的激光制造工艺在TC4表层激光熔覆制备硬度较高的沉积层,研究分析沉积层和TC4基体的显微形貌和综合性能的变化规律,成为目前亟需解决的课题。

国内外学者针对TC4合金表层激光熔覆制备相应合金涂层的修复制造研究方面进行了相关研究。ZHANG等人[2]利用先进的送粉激光技术在TC4表面制备了Ni60涂层,研究分析了涂层的单项力学性能及残余应力分布情况。TIAN等人[3]采用先进的分析技术方法对激光熔覆制备的B4C沉积层进行了微观组织形貌的分析。SUN等人[4]研究了TC4合计表面制备TiCp/Ni基合金涂层的工艺参数优化,并采用先进电子显微设备对沉积层的显微形貌和摩擦性能进行了综合分析和比对。WU等人[5]在TC4表层制备了AlCoCrFeNiTi0.5沉积层组织,分析了沉积层的综合力学性能和熔覆宏观形貌变化规律。MA[6]为了提高TC4表面耐磨性,采用相应CO2激光器,在TC4表层制备了具有较高耐磨度的复合涂层。LIU等人[7]为了制备无气孔和裂纹且组织细致的沉积层,其采用横流CO2激光器,在TC4表层制备了TiB2与Ni的复合涂层,提高了TC4钛合金的耐磨性。ZHANG等人[8]在TC4钛合金表面多道激光熔覆工艺制备了Ni60A自熔性合金, 得到了融合性能较好的激光沉积层组织。ZHENG等人[9]采用正交优化试验,在钛合金表面制备了缺陷较少的Ti-Mo-Si复合型涂层组织。PACHECO等人[10]通过多元回归建立工艺参数(激光功率、扫描速率和送粉速率)与涂层几何特征之间的相关性。MAJUMDAR等人[11]采用连续波CO2激光在Ti-6Al-4V合金表面直接激光熔覆钴,详细研究了工艺参数对界面组织、成分和相的影响,得出了TC4合金制备最佳界面力学和电化学性能的工艺参数。SMUROV等人[12]分析了亮温随激光功率和熔覆速率的变化规律,并采用CCD摄像机作为诊断工具,对同轴粉末注射过程中的粒子飞行速度进行在线监测研究,实现了激光熔覆过程的在线优化。

综上可知,国内外研究学者对TC4合金表层激光熔覆金属合金后的沉积层性能的研究与分析较为深入,但分析现有研究成果发现,针对TC4合金表层激光熔覆制备Fe基(Fe35)合金沉积层的显微组织形貌、显微硬度变化等综合性能的影响规律分析不多[13]。因此,本文中主要研究TC4钛合金表面激光熔覆制备Fe基沉积层过程中,分析经验工艺参数组合对沉积层及TC4基体材料的显微组织形貌、硬度、显微硬度等的影响规律。该研究为延长TC4钛合金部件在航海航空等恶劣环境下的服役时间提供了技术保障。

-

采用TC4合金为激光熔覆基体材料,经过高温回火热处理后,将基体进行去除杂质和氧化皮处理,并用专用的清洁剂进行表面防锈和激光熔覆材料增收处理,且在数控铣床上进行一定的半精加工,最终将试样尺寸控制在65mm×65mm×30mm。铁基粉末材料选择杭州盛镭激光生产的Fe35A合金粉末,其洛氏硬度(Rockwell hardness,HRC)为32HRC,粉末粒度范围为-100目~+270目。Fe基合金和TC4钛合金的主要成分如表 1和表 2所示[14-15]。

element Cr Si Mo C Ni Mn Fe Fe35A 0.15 0.01 0.014 0.0015 0.039 0.0054 balance Table 1. Chemical composition(mass fraction) of Fe35A iron base alloy

element Al V Fe C N H O Ti TC4 0.059 0.04 0.0028 0.0007 0.0004 0.00013 0.00015 balance Table 2. Chemical composition(mass fraction) of TC4 titanium alloy

-

实验过程全程采用博实工业机器人与3kW激光修复系统配备,型号为:SL-GX-3000W;光斑尺寸设置为6mm×3mm。

在特定合理的经验参数范围内,采用平行于光斑长边方向进行激光熔覆实验。研究Fe35A铁基合金沉积层的宏观和微观质量受激光功率、扫描速率、送粉速率等参数的影响规律。试样完成后用高精度洛氏硬度设备对沉积层进行硬度测试,选取洛氏硬度HRC硬度值最大的熔覆实验进行深入扩展实验研究。利用北京时代瑞光的A-41X高精密金相显微仪观察沉积层的金相组织变化情况,综合分析最佳熔覆试样的组织形貌和性能的变化规律,最后利用上海邦亿的HV-1000Z显微维氏硬度仪,对距离Fe铁基沉积表层垂直方向每间距0.1mm深度进行显微硬度测量,测试载荷设置为200g, 保压时间为10s[16]。

1.1. 实验材料

1.2. 实验方案

-

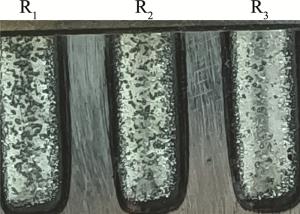

如表 3所示,根据经验熔覆参数实验表进行激光熔覆实验,对应试样洛氏硬度HRC值如图 1所示。观察图 1可知,R3号试样对应的沉积层洛氏硬度HRC值最大为40.2HRC,此时的工艺参数: 激光功率为2.3kW, 扫描速率为9mm/s,送粉速率为10g/min。在经验参数的指导实验下,对3组不同工艺参参数组合制备而成的试样进行深入的检测和研究,并选取洛氏硬度HRC值最大的试样进行扩展实验研究,将所得的数据在相关曲线图上进行表达,综合分析TC4表面激光熔覆Fe基合金涂层的显微组织和性能的变化规律。

No. laser power/kW scanning speed/(mm·s-1) powder feeding speed/(g·min-1) R1 2.3 5 8 R2 2.3 7 9 R3 2.3 9 10 Table 3. Experimental parameters of laser cladding test

-

图 2所示为经验参数实验下TC4表面Fe35A铁基沉积层的宏观形貌状态。深入观察图 2不难发现,沉积层整体形状最为饱满的是R3试样,R1和R2整体饱满度均略小于R3;且R1和R2沉积层较R3表面存在较多的裂纹与坑状形貌,沉积纹路较为杂乱,图中宏观形貌最差的是R1试样;再次观察R3发现,其沉积层表面质量较高,且沉积纹路均匀,沉积层细致美观,由此可知,在R3经验参数组实验下,Fe35A铁基沉积层宏观形貌及表面质量最佳。

-

将沉积层表面质量最佳的R3试样和最差的R1试样,再数字化测试实验室内进行微观金相组织的观察,研究分析沉积层中部熔池微观金相组织形貌的差别与特征,如图 3a和图 3b所示。

观察图 3a可知,R1试样沉积层微观金相组织晶粒与晶粒之间的间距较大,且晶粒未细化,晶粒以粗大粒状表现为主,导致该区域沉积层硬度值较低;综合观察图 3b可知,R3试样微观金相组织细化明显,晶粒以细致均匀排列为主,晶粒与晶粒之间排列紧凑细致,晶粒以细小密状排列分布为主,此时沉积层中部熔池整体硬度较高。

-

结合图 1,选择最佳沉积层R3试样,在数字化测试实验室内进行切面3维显微形貌的分析检测,如图 4所示。综合分析图 4不同功能区3维形貌图可知,根据不同区域的分布及测试情况,可将Fe基沉积层分为四大区域:基体区、沉积层顶层热影响区、沉积层与基体融合区、沉积层区。深入观察各区域的3维显微形貌可知,沉积层与基体融合区显微组织融合较好,且晶体组织细致均匀;沉积层顶层热影响区显微组织变化活跃,排列复杂且晶相各异;TC4基体组织较为稳定,晶体形状饱满紧凑;沉积层区晶体细化明显,且排列均匀,显微结构规则细致。

-

再次结合表 3,选取最佳工艺参数组合熔覆试样R3,将其进行整体切面后测量所得沉积层区域的几何形状宽度和高度为5.5mm×0.62mm。显微硬度值的测量则利用高精度显微维氏硬度仪,选取距离沉积区顶层间距差为每0.1mm的位置进行检测,其值变化规律曲线如图 5所示。

结合图 4,综合分析图 5可知,从左至右划分为0mm~0.4mm为沉积层顶层的热影响区、0.4mm~1.0mm为沉积层区、1.0mm~1.6mm为沉积层底层的热影响区、1.6mm~2.0mm为TC4基体区。分析图 5不难发现,沉积层顶层的热影响区、沉积层区和沉积层底层的热影响区三大区域的维氏硬度(Vickers hardnes,HV)值均高于TC4基体,其中沉积层区的显微硬度平均值在645.5HV,最大值可达656HV,力学性能明显优于基体区。由于沉积层顶层的热影响区内晶相组织结构变化复杂且冷却速度较快,导致该区域显微硬度值较低[16];分析图 5可知,沉积层区中试样的显微硬度迅速增大,该区域处于试样的中部位置,该位置散热速度缓慢,且晶粒逐步细化,产生了大量的马氏体组织[16],促使沉积层区的显微硬度大幅提高;随着检测深度的再次增大,超出沉积层底部热影响区后试样的显微硬度HV值迅速降低至204HV并趋于稳定,此时进入TC4基体区, 表现为TC4的力学性能。

2.1. 不同工艺参数下沉积层洛氏硬度对比

2.2. 工艺参数对沉积层宏观形貌的影响

2.3. 工艺参数对沉积层显微组织的影响

2.4. 工艺参数对最佳沉积层组织性能影响

2.5. 工艺参数对沉积层显微硬度的影响

-

(1) 在TC4表层激光熔覆Fe基合金实验过程中,当经验参数控制在激光功率2.3kW、扫描速率为9mm/s、送粉速率为10g/min时,能够得到高质量的Fe基合金沉积层,其表面纹路均匀,沉积层规整饱满,宏观形貌最佳,沉积层表层洛氏硬度高达40.2HRC。

(2) 在最佳经验参数实验下,TC4钛合金基体与Fe基合金沉积层熔合度高,显微观察沉积层内部金相组织形貌发现,其晶粒细化明显,排列紧凑,显微形貌好,显微硬度平均值达645.5HV,最高达656HV。实现了在TC4钛合金表面高质量制备Fe基合金沉积层的目的。

Map

Map

DownLoad:

DownLoad: